Project planning know-how as a competitive advantage

“With our customers such as Toyota, Nissan or Renault in India, we have become one of the leading companies in the automotive industry,” explains Chairman and Managing Director Bijay Krishna Shrestha. TGSIN now employs roughly 850 employees and had a turnover last year approx. 43 m Euro.

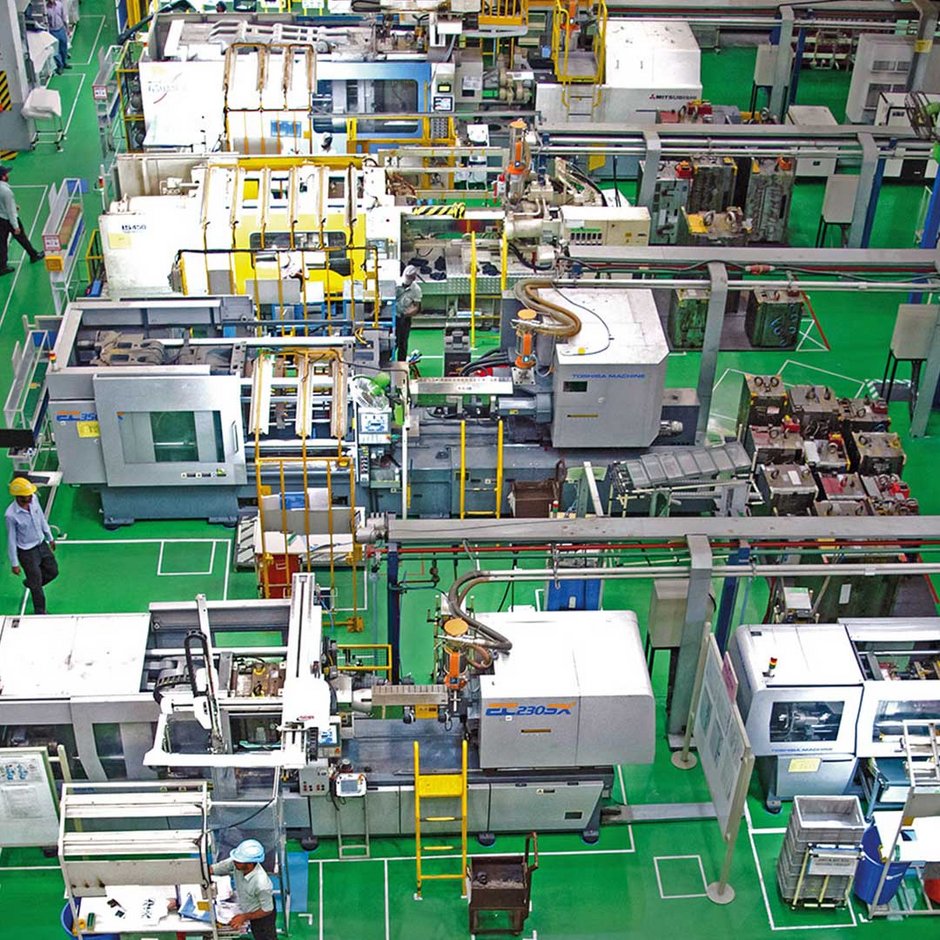

In Bengaluru, at Toyota Techno Park they are spread over approx. 23,400 m2 of production area. Injection Moulding (Interior and Exterior), Resin Painting (Interior and Exterior), Safety systems parts (Air bags – Driver and Passenger air bags) are their core manufacturing functions. They have around 25 Injection Moulding machines with tonnage ranging from 80 t to 3500 t clamp force. Bumpers, Grille radiators, Wheel caps, Back door garnish (Exterior parts) and Instrument panels (with Tear milling and Vibration weld process) Pillar parts, Console module and Armrest (Interior parts) are in their product profile.

Further, during a production expansion in the year 2014, TGSIN was looking for a provider of a drying and conveying system that was based locally and also provided technically high-quality solutions that met the company’s high demands. motan-colortronic India was the answer.

“For production, TGSIN use a compartmentalized cell principle. This means that every processing machines has its own individual supply, like many Japanese companies prefer,” explains Sales Manager Anandakumar Ramachandran. “In 2010 the company bought 6 LUXOR HD 250 hot air dryers and 6 METRO HPE 06 material loaders with the same concept,” he reports of the beginning of the partnership.

However, the cell principle and the accompanying material supply directly to the processing machines also has some disadvantages, such as noise, heat, dust, shortage of space and granule waste in the immediate vicinity of the machine. “This is where we suggested a centralized drying and conveying system for TGSIN‘s second phase of expansion with nine new injection molding machines, to save space in production and increase cleanliness around the machine and, above all, improve energy efficiency. This is how we could set ourselves apart from the competition, “explains Ramachandran.

For the new central material supply a mezzanine floor was installed. Starting with material supply, the drying system and part of the conveying system is also set-up on the mezzanine. The material comes in 25 kg bags and 750 Kg bags, the material feed station for this is directly opposite the drying system to prevent long distances.

Because of the wide variant of polymers used, the central material conveying system was designed as a machine specific system. This means that every injection moulding machine has its own supply line and the material selection is done at a coupling station. The manual METROCONNECT U coupling table provides flexibility for material supply. The result is that multiple machines can be connected to one material feedline. Another advantage of the central conveying systems is the relocation of the conveying blower to a central location. By doing so, the processing machine and its immediate vicinity are free from contamination, heat and noise.

By implementing the concept of a central drying system instead of individual dryers, the total power of the dryers was reduced from 353 kW to 159.8 Kw. This successful result is due to a clever combination of air generators and drying bins with different liter volumes, that was tested and optimized beforehand at the motan-colortronic India technical center.

“motan-colortronic India supplies solutions, not just products,” Ramachandran summarizes. “Another one of our strengths is our know-how in project planning, which sets us apart from out competition in India,” he says with confidence. “The products we manufacture in India are of the exact same quality as those made in Germany. Due to an intensive search for local suppliers that provide consistently high quality as well as our intensively trained production employees, we can absolutely guarantee this.”

Mr. Balamurugan, Assistant General Manager and responsible for Machine Maintenance at TGSIN say: “We chose motan-colortronic because of their high-quality products and reliability. Additional criteria were the technical competence of the company, increased energy efficiency and fewer down times. Although that is not completely accurate. Down time is currently at zero.” Additionally, the new units and systems have resulted in much better cleanliness in production area and the service support through motan-colortronic is ideal.